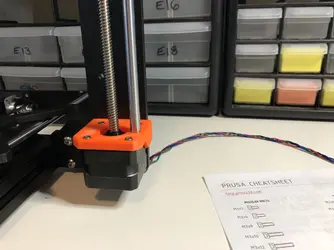

If you've been following the 3D Print Project Feed thread, you might know we're trying to build a 1:8 scale model of the DeLorean time machine from Back to the Future. The printer we had was a Prusa i3 MK3 built years ago, and I found a problem with the hotend while doing some maintenance after aa failed print that forced me to pause things for a bit.

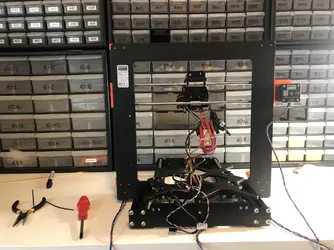

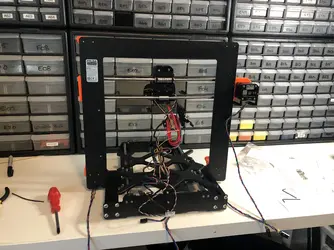

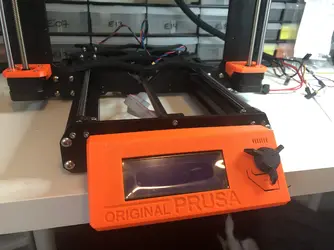

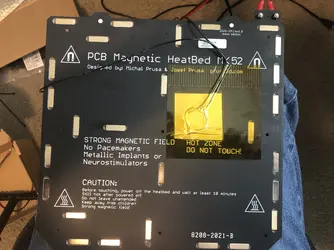

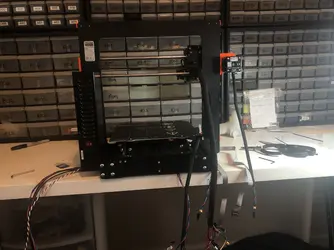

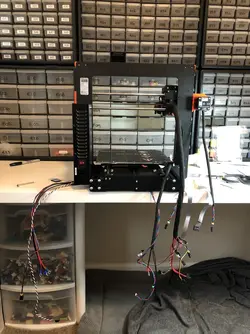

But now we're back, with bigger and better toys. We've just received our replacement, a brand new Prusa i3 MK3S+... And it's something that requires quite a bit of assembly.

Starting Saturday morning, 5/21/22 I will start livestreaming its construction and hanging out on Twitch while I do it. Nothing too structured, maybe an Ancient Aliens or Back to the Future marathon in the corner while I work on it and chat with whomever drops in.

This probably won't be finished in a single sitting, but I'll keep this Showcase item up to date with future streams and overall progress

But now we're back, with bigger and better toys. We've just received our replacement, a brand new Prusa i3 MK3S+... And it's something that requires quite a bit of assembly.

Starting Saturday morning, 5/21/22 I will start livestreaming its construction and hanging out on Twitch while I do it. Nothing too structured, maybe an Ancient Aliens or Back to the Future marathon in the corner while I work on it and chat with whomever drops in.

This probably won't be finished in a single sitting, but I'll keep this Showcase item up to date with future streams and overall progress

Last edited by a moderator: